Three cable type steel wire rope grille cleaning machine

Use three-cable wire rope grid decontamination machine (referred to as wire rope grid decontamination machine), it is suitable for large and medium-sized waterworks, rain/sewage lifting pump stations. At the water inlet of sewage treatment plants and power plants, etc., intercept and remove coarse floating debris and bottom sediment in the water, protect the pump impeller, and reduce the treatment load of subsequent process equipment.

Category:

Keyword:Sewage disposal 丨 Drug

Description

Use three-cable wire rope grid decontamination machine (referred to as wire rope grid decontamination machine), it is suitable for large and medium-sized waterworks, rain/sewage lifting pump stations. At the water inlet of sewage treatment plants and power plants, etc., intercept and remove coarse floating debris and bottom sediment in the water, protect the pump impeller, and reduce the treatment load of subsequent process equipment.

Structure and working principle

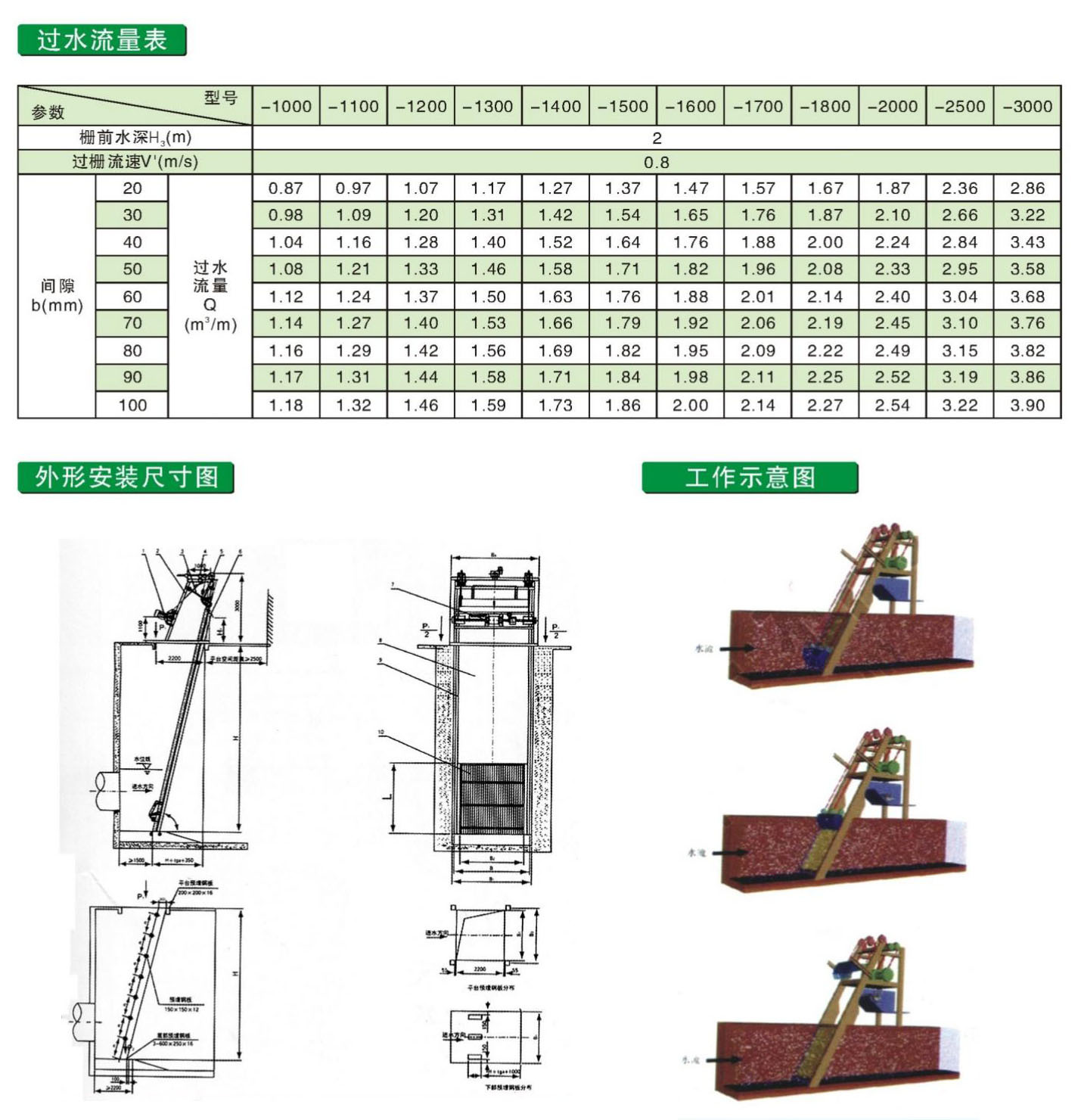

The frame of the equipment is fixed at the upper end of the wellhead, composed of fixed grid strips over the water grid surface, when the sewage flows through the grid surface, the debris larger than the grid gap is intercepted: the bucket is first driven by the rake motor, stops after completing the opening action, and then is driven by the lifting motor, and under the control of the height limiter, stops after descending to the bottom of the grid well along the guide rails on both sides, and automatically turns on the rake motor again, stops after completing the rake action, and the lifting motor starts again, Under the traction of the wire rope, the bucket is inserted into the gap of the grid strip, the intercepted debris is picked up, and rises along the grid surface and slag baffle, under the control of the height limiter, after reaching the discharge port position, the lifting motor stops, and the cleaning scraper at the upper frame automatically scrapes the debris with the rising action of the rake bucket, and falls into the conveyor or garbage trolley from the discharge port, and the cleaning process is completed.

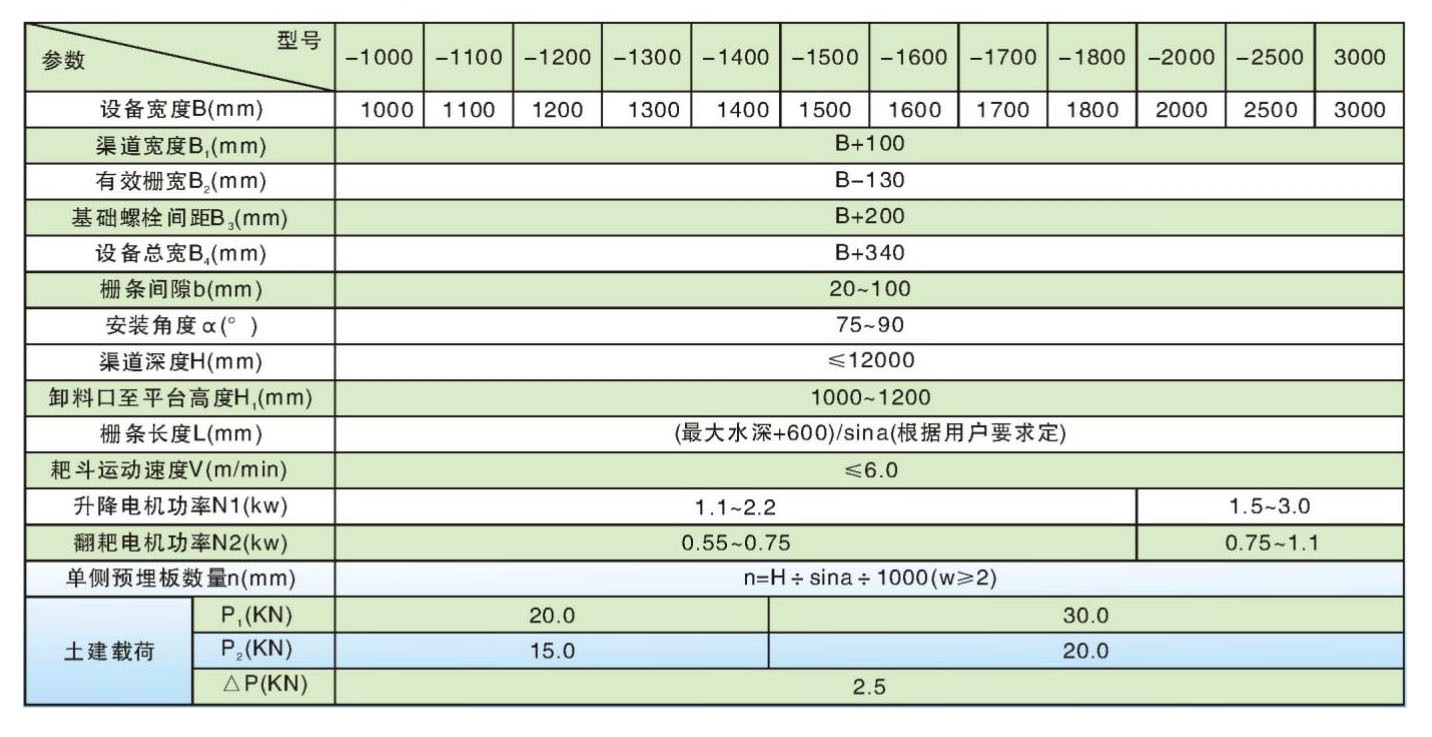

Technical data and installation size chart

Main features

: The frame structure is unique, and it adopts split type, that is, the upper frame and the lower grille group are not integrated;

The rake bucket adopts a special large-capacity, heavy-duty type "grab type", which ensures its smooth operation through the roller guide and wire rope traction on both sides:

there is an unloading scraping plate on the upper frame, which can effectively scrape the dirt in the rake bucket to the discharge port for discharge, and the discharge is clean and thorough;

The lifting and opening of the bucket are two independent drive systems, which run according to the set program under the control of the electrical system;

The equipment is easy to operate, and the operation of the equipment can be controlled directly in situ/remotely.

Related products

Message