Wedge shaped spiral grid cleaning machine

wedge form screw grid decontamination machine is to absorb and digest foreign advanced technology, combined with the specific actual situation of China's water treatment workers, by the company itself developed a new type of equipment, suitable for urban sewage treatment plant fine grid, is the interception of dirt collection, transportation and pressing of three functions as one of the new products. Structure and working principle

Category:

Keyword:Sewage disposal 丨 Drug

Description

Use

wedge form screw grid decontamination machine is to absorb and digest foreign advanced technology, combined with the specific actual situation of China's water treatment workers, by the company itself developed a new type of equipment, suitable for urban sewage treatment plant fine grid, is the interception of dirt collection, transportation and pressing of three functions as one of the new products.

Structure and working principle

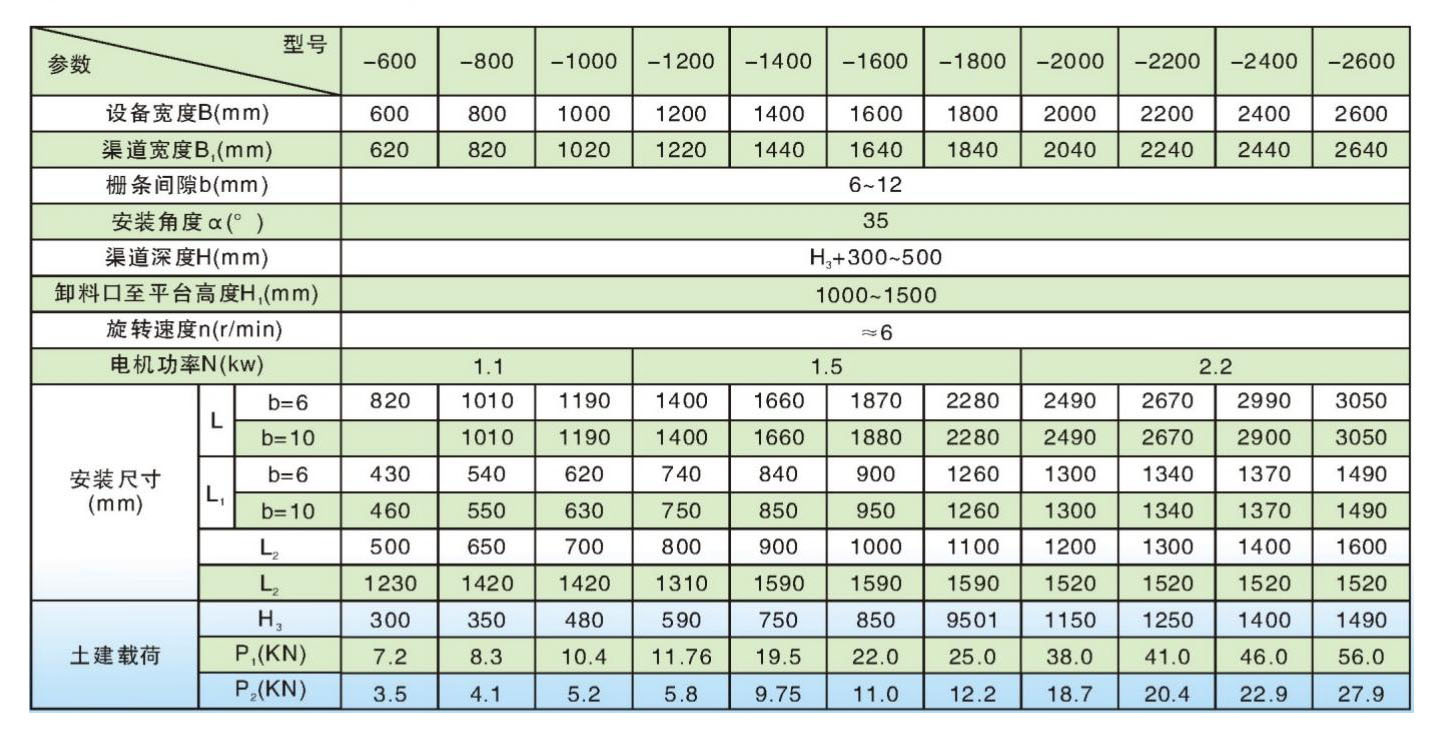

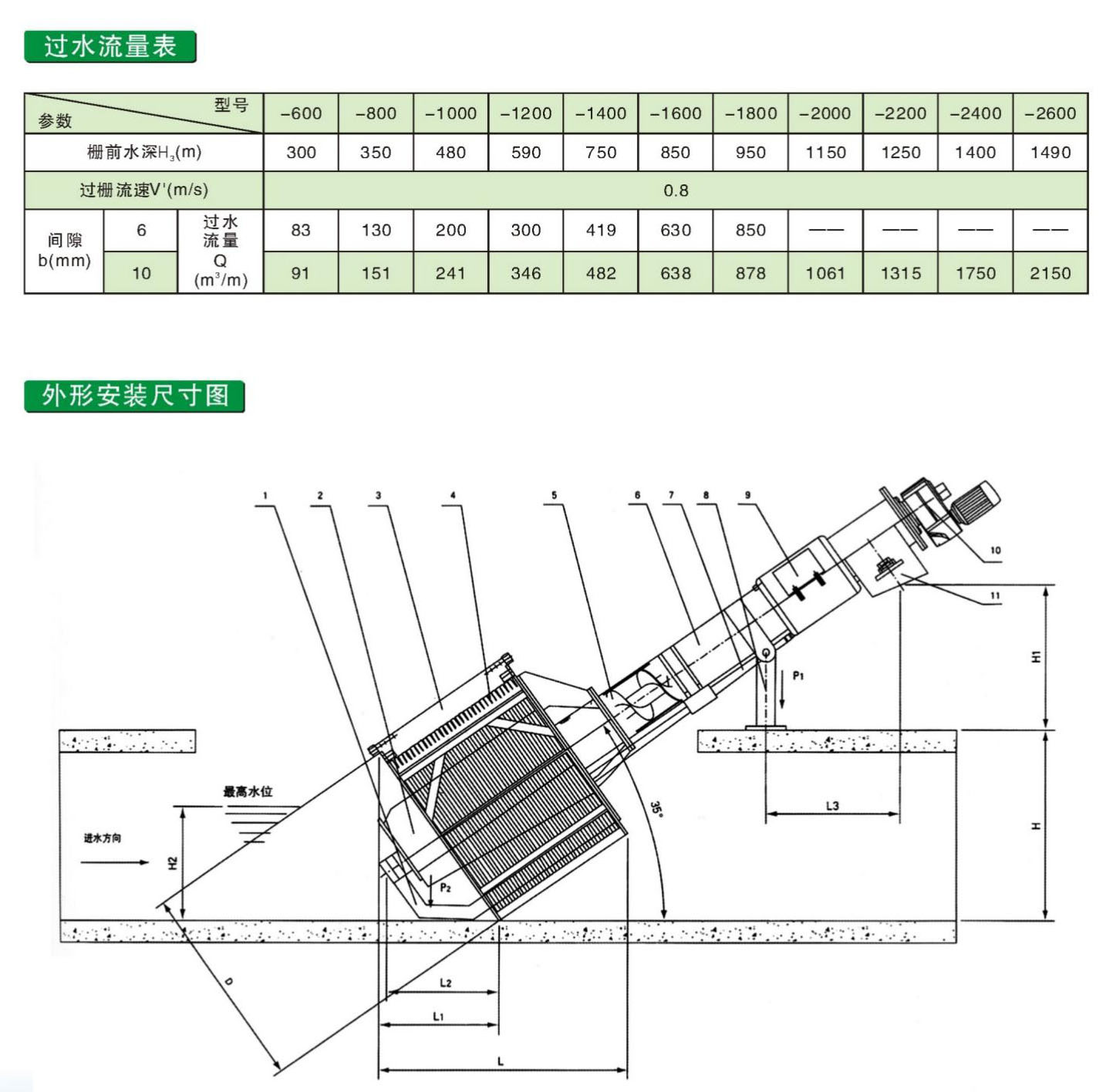

The equipment consists of a series of circular wedge baskets composed of ring grids as the grid surface, and the horizontal plane at 35 ° installed in the water channel, when the sewage flows into the grid basket from the grid pass, the filter residue larger than the grid gap is intercepted and deposited on the inner surface of the grid basket, the toothed scraper is driven by the motor to rotate, the filter residue scraped above the grid basket by gravity to fall, while the motor reverses, driving the toothed scraper to reverse, and through the slag cleaning plate the intercepted filter residue falls into the slag tank, After the filter residue is conveyed, extruded and dewatered through the center screw, it falls into the material box or conveyor by the discharge port for external transportation technical

parameters and installation size table

Main features

: The whole machine has compact structure, small footprint, easy installation, operation and maintenance, small gap between the grid, and

can generally be designed in the range of 6~12mm;

High sewage interception efficiency, closed conveying, no pollution to the environment;

The equipment can be fully automatic control, stable operation, low energy consumption, low noise;

Automatic cleaning is implemented during the operation of the equipment and never clogged.

1. Scraping rake 2, collecting hopper 3, sieve grid body 4, slag cleaning plate 5, transfer press rod 6, transfer press cylinder 7, return pipe 8, outrigger 9, cleaning cylinder 10, drive device 11, slag discharge port

Related products

Message