Drum type spiral grid cleaning machine

drum type screw grid decontamination machine is to absorb and digest foreign advanced technology, combined with the specific actual situation of China's water treatment project, by the company itself developed a new type of equipment, suitable for the fine grid of urban sewage treatment plant, but also the collection of grid dirt interception collection, transportation and pressing of three functions as one of the new products.

Category:

Keyword:Sewage disposal 丨 Drug

Description

Use

drum type screw grid decontamination machine is to absorb and digest foreign advanced technology, combined with the specific actual situation of China's water treatment project, by the company itself developed a new type of equipment, suitable for the fine grid of urban sewage treatment plant, but also the collection of grid dirt interception collection, transportation and pressing of three functions as one of the new products.

Structure and working principle

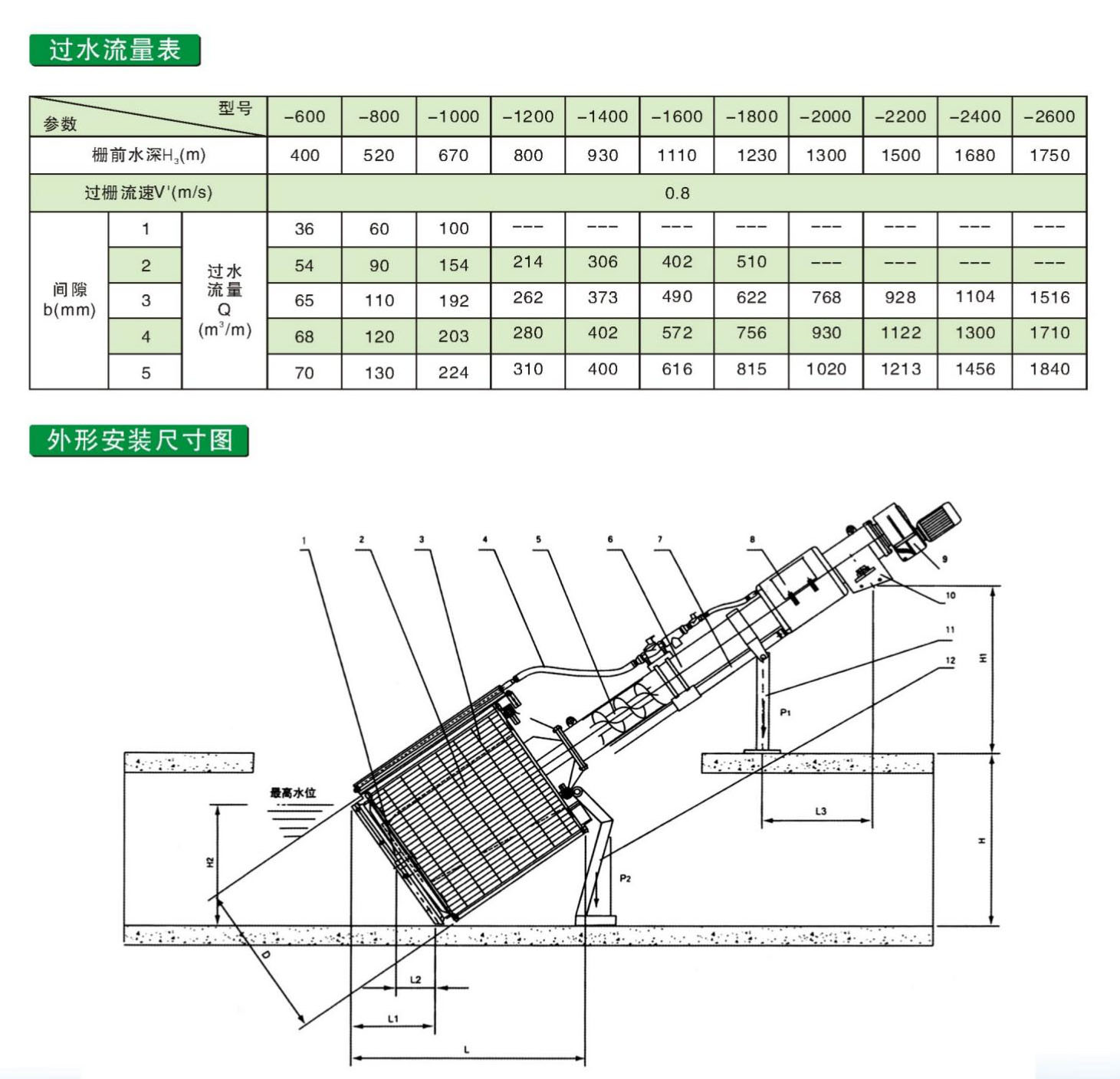

The equipment adopts rotary drum spiral type, by the round screen barrel as the grid surface, and the horizontal plane at 35 ° installed in the water channel, when the sewage flows from the end of the grid into the screen cylinder, the filter residue larger than the grid gap is intercepted, deposited on the inner surface of the screen cylinder, the entire screen cylinder is driven by the motor to rotate, the slag cleaning brush above the screen cylinder and the flushing mechanism to clean the screen surface, the filter residue is flushed into the central material tank, lifted by the conveying screw, after pressing and dehydration, It is dropped into the material bin or conveyor by the discharge port for external transportation.

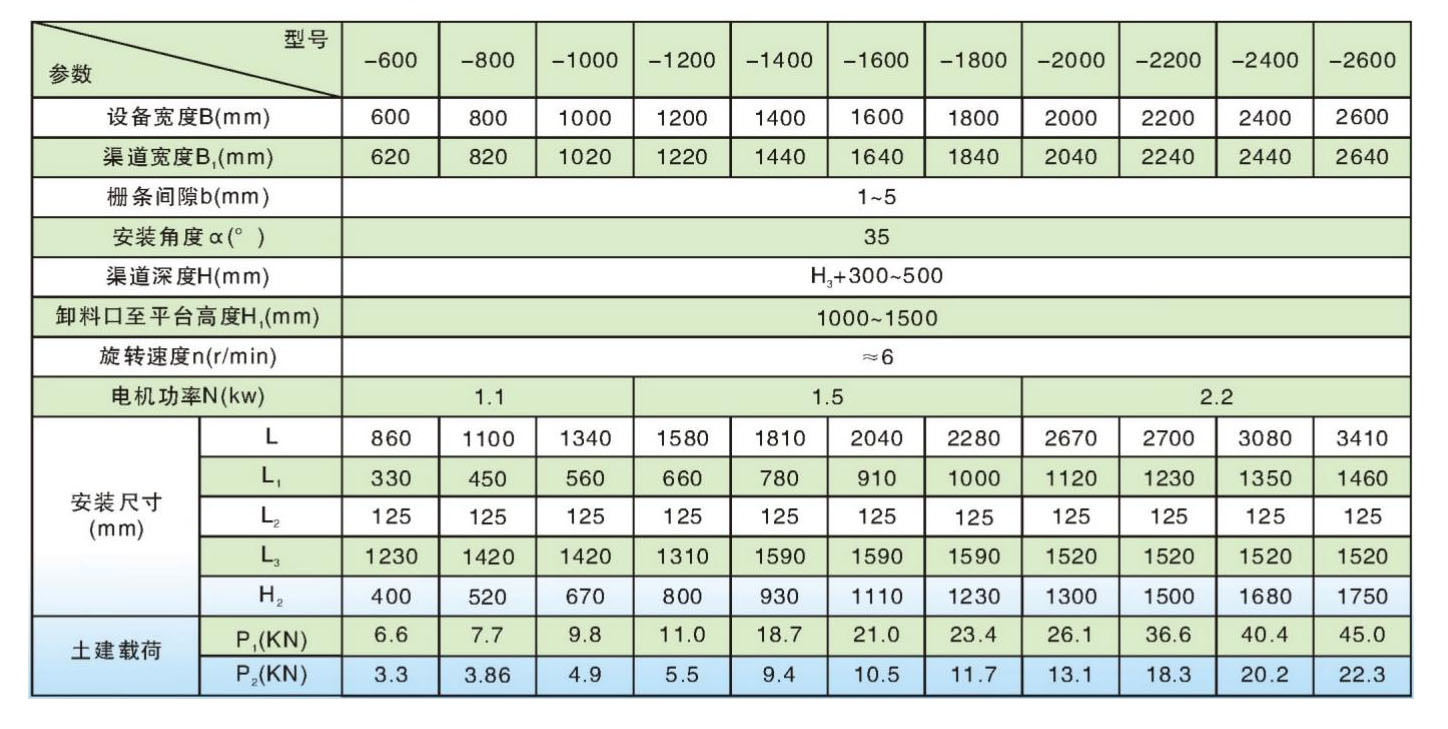

Technical data and installation size chart

Main features

: The whole machine has compact structure, small footprint, easy installation, operation and maintenance, small gap between the grid, and

can generally be designed in the range of 6~12mm;

High sewage interception efficiency, closed conveying, no pollution to the environment;

The equipment can be fully automatic control, stable operation, low energy consumption, low noise;

Automatic cleaning is implemented during the operation of the equipment and never clogged.

1. Rotating arm 2, collecting hopper 3, screen grid body 4, washing device 5, transfer press rod 6, transfer press cylinder 7, return pipe 8, cleaning cylinder 9, drive device 10, slag discharge port 11, rear leg 12, front leg

Related products

Message