Oxidation ditch aeration to butterfly

oxidation ditch aerator belongs to the horizontal shaft disc type surface push flow aerator in the mechanical aerator. The aerator is composed of an aeration turntable, a horizontal shaft and its bearings at both ends, a motor and a reducer. Made of lightweight, high-strength, corrosion-resistant FRP die-casting, the overall structure is reasonable, light weight, high strength, the surface of the turntable has trapezoidal bumps, circular pits, so as to increase the amount of air brought into the mixture, enhance the ability to cut bubbles, push the mixture, the installation density of the turntable can be adjusted, easy to adjust the number of turntables installed on the unit according to oxygen demand, each turntable can be independently disassembled and assembled, convenient for maintenance.

Category:

Keyword:Sewage disposal 丨 Drug

Description

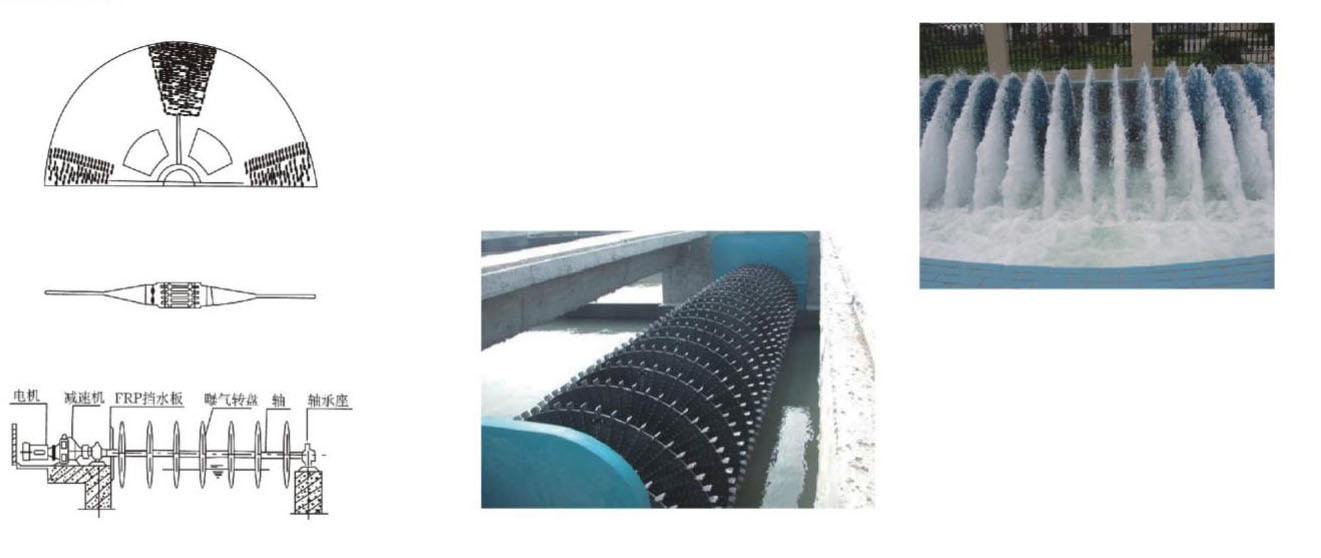

The structural

oxidation ditch aerator belongs to the horizontal shaft disc type surface push flow aerator in the mechanical aerator. The aerator is composed of an aeration turntable, a horizontal shaft and its bearings at both ends, a motor and a reducer. Made of lightweight, high-strength, corrosion-resistant FRP die-casting, the overall structure is reasonable, light weight, high strength, the surface of the turntable has trapezoidal bumps, circular pits, so as to increase the amount of air brought into the mixture, enhance the ability to cut bubbles, push the mixture, the installation density of the turntable can be adjusted, easy to adjust the number of turntables installed on the unit according to oxygen demand, each turntable can be independently disassembled and assembled, convenient for maintenance. The horizontal shaft is made of thick-walled seamless steel pipe, and the surface is treated with special FRP anti-corrosion. It can be processed into various lengths according to user requirements, which can fully meet the needs of various large, medium and small oxidation ditches for aeration units. The drive unit adopts single-stage cycloid pinwheel reducer and series motor, which can be manufactured into horizontal or vertical according to user requirements, and can choose an adjustable speed motor, which is convenient to adjust the speed of the unit according to oxygen demand.

Schematic diagram

Technical performance

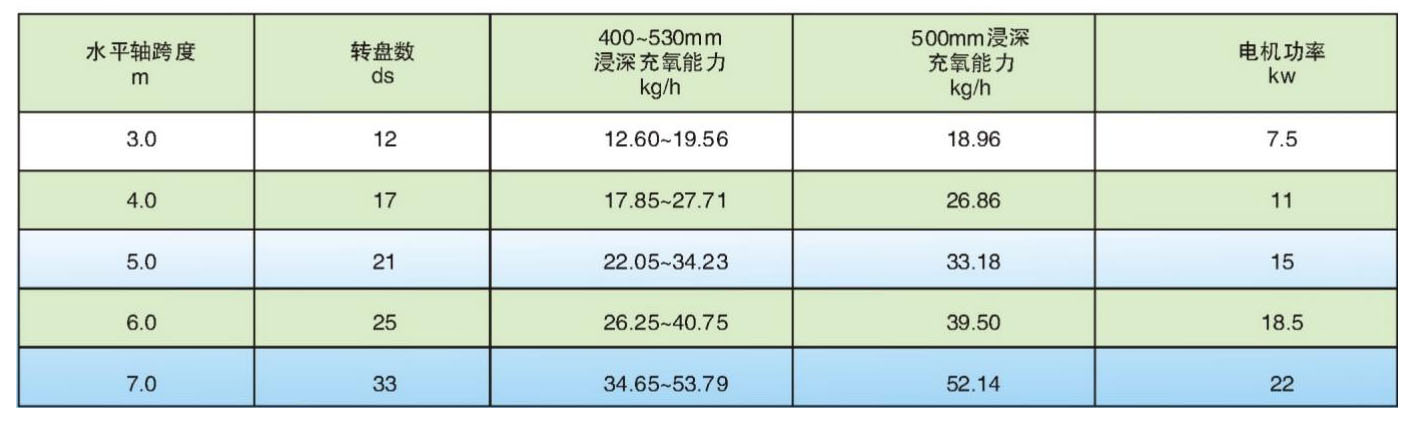

: aeration turntable diameter: 1400mm, applicable speed: 50~55rpm; Economic speed: 50rpm applicable immersion depth: 400~530mm; Economic immersion depth: 500mm single disc standard clean water oxygenation capacity: 0.82~1.63kgoh·ds

Oxygenation efficiency (power efficiency): 254~316kgO/kw·h (in terms of shaft power)

Applicable working water depth: <5.2m horizontal axis span: single axis≤9m; Dual-axis 9~14m aeration disc installation density: <5ds/m design power density: 10~12.5w/m3

The performance of the whole machine with a deflector plate downstream of 50rpm

Related products

Message