Diaphragm type microporous aerator

1, the gas diffusion rubber plate of the diaphragm microporous aerator is made of high-quality synthetic rubber, the bubble diameter diffused by the rubber diaphragm is small, the gas-liquid interface area is large, therefore, it has a high mass transfer rate and high oxygenation efficiency, so that compared with other current aeration devices, it can greatly save electricity consumption and reduce the operating cost of sewage treatment.

Category:

Keyword:Sewage disposal 丨 Drug

Description

Introduction

1, the gas diffusion rubber plate of the diaphragm microporous aerator is made of high-quality synthetic rubber, the bubble diameter diffused by the rubber diaphragm is small, the gas-liquid interface area is large, therefore, it has a high mass transfer rate and high oxygenation efficiency, so that compared with other current aeration devices, it can greatly save electricity consumption and reduce the operating cost of sewage treatment.

2, rubber diaphragm on a large number of self-closing holes, with oxygenation and stop running, eyelets can automatically open and close, therefore, do not produce eyelet blockage, staining and other drawbacks, at the same time, the air into the aerator does not need to be dust purified, when the aeration tank stops running, the sewage mixture will not be poured can reduce a lot of operating costs and maintenance workload. 3. Because the diaphragm microporous aerator can be fully spread at the bottom of the aeration tank, the dissolved oxygen in the pool is uniform, which can be applied to various pool types and depths, and the original aeration tank can also be modified to improve the effect. 4. Because the diaphragm microporous aerator gas diffusion plate is made of high-quality rubber, it has excellent physical and mechanical properties, and the tray, accessories and air ducts are made of engineering plastics and polypropylene, so it is not afraid of rust, which greatly reduces the workload of operation and maintenance.

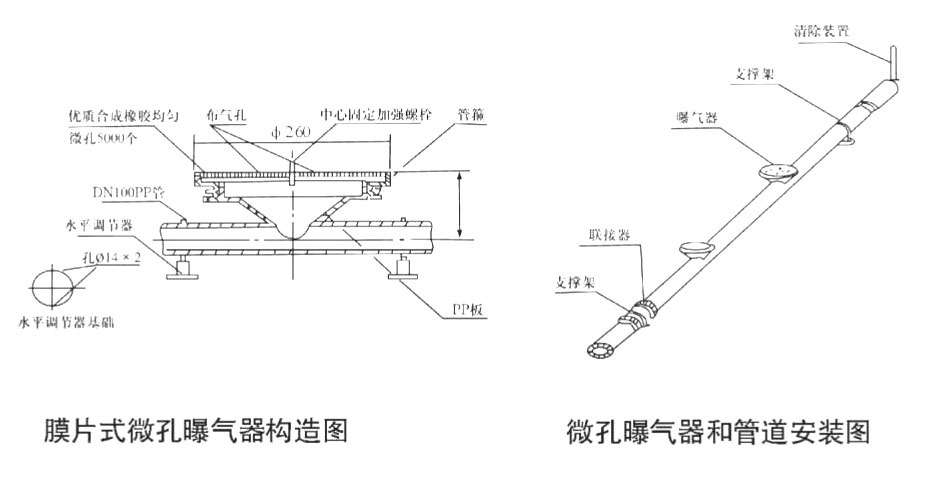

The basic structure

of the diaphragm microporous aerator system is mainly composed of aerator base, upper spiral gland plate, air equalizer, synthetic rubber diaphragm and other components, and its component rights are made of engineering plastics, when assembling, as long as the microporous rubber diaphragm is set on the air equalizer, and placed in the base of the aerator with a sealing line, and then screwed with the upper spiral gland to tighten.

The air pipeline adopts polypropylene or ABS engineering plastic pipe (selected according to user needs), and there is a 3/4 internal thread joint welded on it, and the microporous aeration head is directly screwed on the gas distribution pipeline, which is easy to install and use, which is conducive to maintenance and repair (see Figure 260) YMB-| type microporous aerator diameter is D=250mm (or 215): Type D=189mm (or 2100) has 2500-<> open and closed eyelets arranged in a certain regular arrangement on the synthetic rubber diaphragm, When inflating, the air passes through the air distribution pipeline, the air equalizer, evenly enters between the rubber diaphragm, under the action of air pressure, the diaphragm is slightly bulging, the eyelets are opened, to achieve the purpose of air diffusion, when the air supply is stopped, because the pressure between the diaphragm and the air manifold gradually decreases, the eyelets gradually close, when the pressure all disappears, due to the water pressure and the resilience of the diaphragm itself, the diaphragm is compacted on the air equalizer.

In view of the above structure and the good characteristics of the diaphragm itself, it is impossible to produce backfilling of the mixture in the aeration tank, therefore, it will not stain the eyelets, on the other hand, when the eyelets are opened, due to the elastic action of the rubber, the small amount of dust contained in the air will not cause the aerator gap to be blocked.

Main performance parameters

1, aerator size|type D=260mm (or 250); Type D=215mm (or 189)

2, the average aerator diaphragm aperture is 80-100um

3, air flow 1.5-3m/n

service area|Type 0.5-07m2; l type 0.35-05m 4 5 oxygen total transfer area coefficient kla(20C) 0.204-0.337mm-1

6. Oxygen utilization rate (water depth 32m) 18.4-27.7%

7, oxygenation capacity 0.112-0185kgO/mh

8, oxygenation dynamic efficiency

4.46-5.19kgO/kw.h

9. Aerator resistance 180-280mm. H2O

Related products

Message