Single hole membrane aerator

The single-hole membrane aerator is a new type of air supply and oxygenation composed of upper and lower tube clamps made of ABS material and supporting rubber diaphragm. In the aeration biological filter process, the single-porous membrane aerator meets the sufficient and stable oxygen required for microbial metabolism on the filter media by forcibly transporting high flow rate air to the filter layer. The uniform air distribution and stable air volume inside the entire filter tank increase the organic load requirements of the system.

Category:

Keyword:Sewage disposal 丨 Drug

Description

Product introduction

: The single-hole membrane aerator is a new type of air supply and oxygenation composed of upper and lower tube clamps made of ABS material and supporting rubber diaphragm. In the aeration biological filter process, the single-porous membrane aerator meets the sufficient and stable oxygen required for microbial metabolism on the filter media by forcibly transporting high flow rate air to the filter layer. The uniform air distribution and stable air volume inside the entire filter tank increase the organic load requirements of the system.

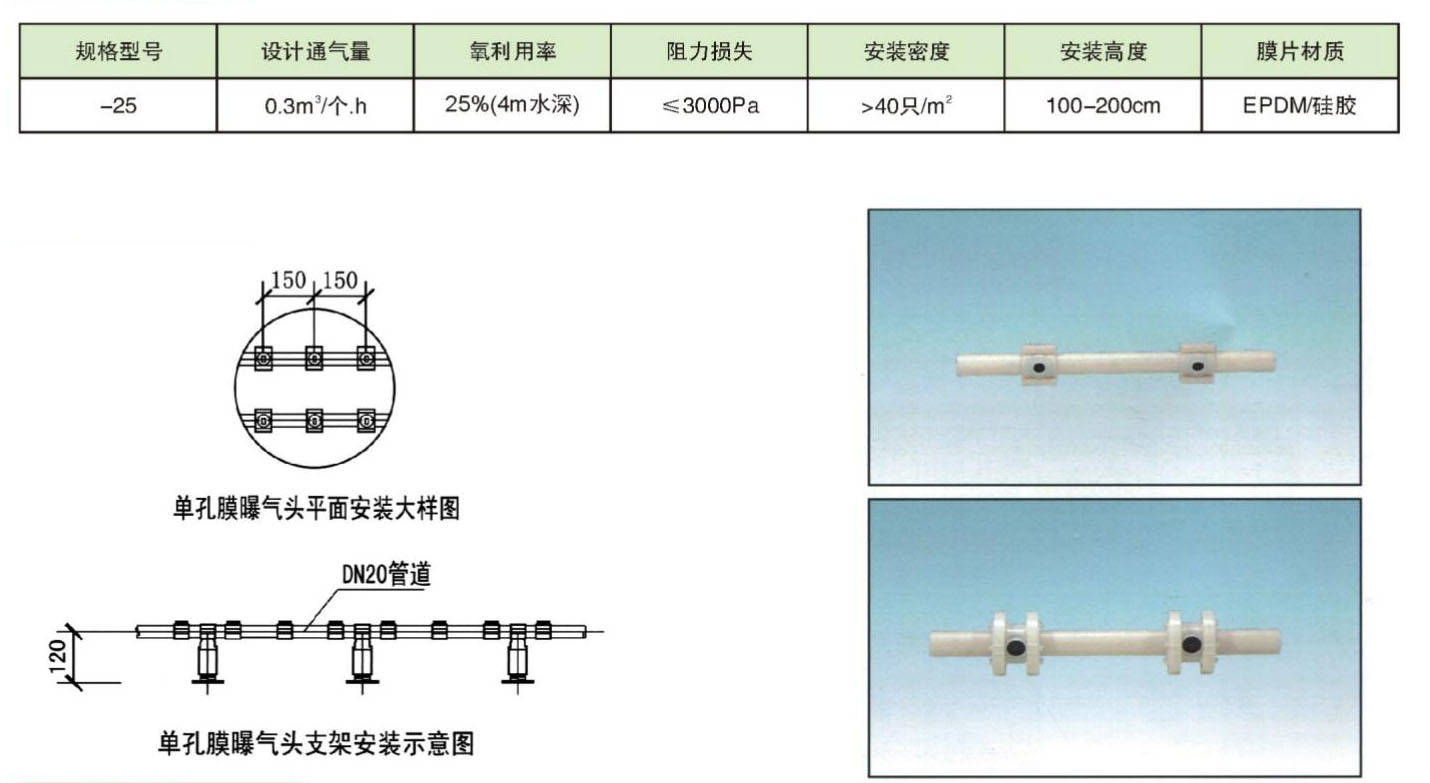

The unique upper

and lower pipe interlayer connection method of the product features the maximum convenience of the installation work, and a single aerator can be freely disassembled and assembled without cutting off the gas supply pipeline. The overall structural design is sturdy, avoiding damage during multiple handling. The air flow outlet of the upper clamp is provided with concave and convex aliquots, which avoids the influence of the accumulated filter material layer on the diaphragm tension.

Technical data sheet

Installation matters and storage

1, pipeline storage, transportation should be bundled, the weight of each bundle is generally 50KG, stacked horizontally on the flat ground, stacking height should not exceed 15 meters, should try to avoid irregular stacking and exposure.

2. The knot surface must be kept clean, and it is strictly forbidden to bond in a humid environment and keep the tool clean.

3. In the process of applying glue, smoking is strictly prohibited.

4. Before connecting the pipeline, clean up the debris inside the pipeline to avoid other particles such as building materials entering the pipeline.

5. In the design process of the aeration pipe network, the adjustable fixed bracket must be installed according to the distance of about 05~0.8 meters.

6. After the pipe network is assembled, it needs to be flattened in time, and the drop height should not exceed 1cm, and the clean water leakage test should be carried out to ensure that there is no interface leakage before putting it into

use.

Related products

Message