Mechanical stirring clarifier mixer, scraper

Uses : mechanical mixing clarifier mixer, scraper is the main supporting equipment of the national general mechanical accelerated clarifier. It is often used in the clarification stage of water supply and drainage treatment process such as raw water treatment of domestic drinking water and industrial water supply and industrial wastewater tertiary treatment, water softening treatment. When using the mixer alone, the turbidity of the raw water entering the clarifier generally does not exceed 1000mg/L, and the short time does not exceed 3000mg/L; At the same time, when supporting the scraper, the turbidity of entering the clarifier can reach 1000-5000mg/L, and the short time does not exceed 10000mg/L; This device has an installation. Convenient maintenance and management: stable operation, safe and reliable: adjustable return flow and other characteristics.

Keyword:Sewage disposal 丨 Drug

Description

Uses

: mechanical mixing clarifier mixer, scraper is the main supporting equipment of the national general mechanical accelerated clarifier. It is often used in the clarification stage of water supply and drainage treatment process such as raw water treatment of domestic drinking water and industrial water supply and industrial wastewater tertiary treatment, water softening treatment.

When using the mixer alone, the turbidity of the raw water entering the clarifier generally does not exceed 1000mg/L, and the short time does not exceed 3000mg/L; At the same time, when supporting the scraper, the turbidity of entering the clarifier can reach 1000-5000mg/L, and the short time does not exceed 10000mg/L; This device has an installation. Convenient maintenance and management: stable operation, safe and reliable: adjustable return flow and other characteristics.

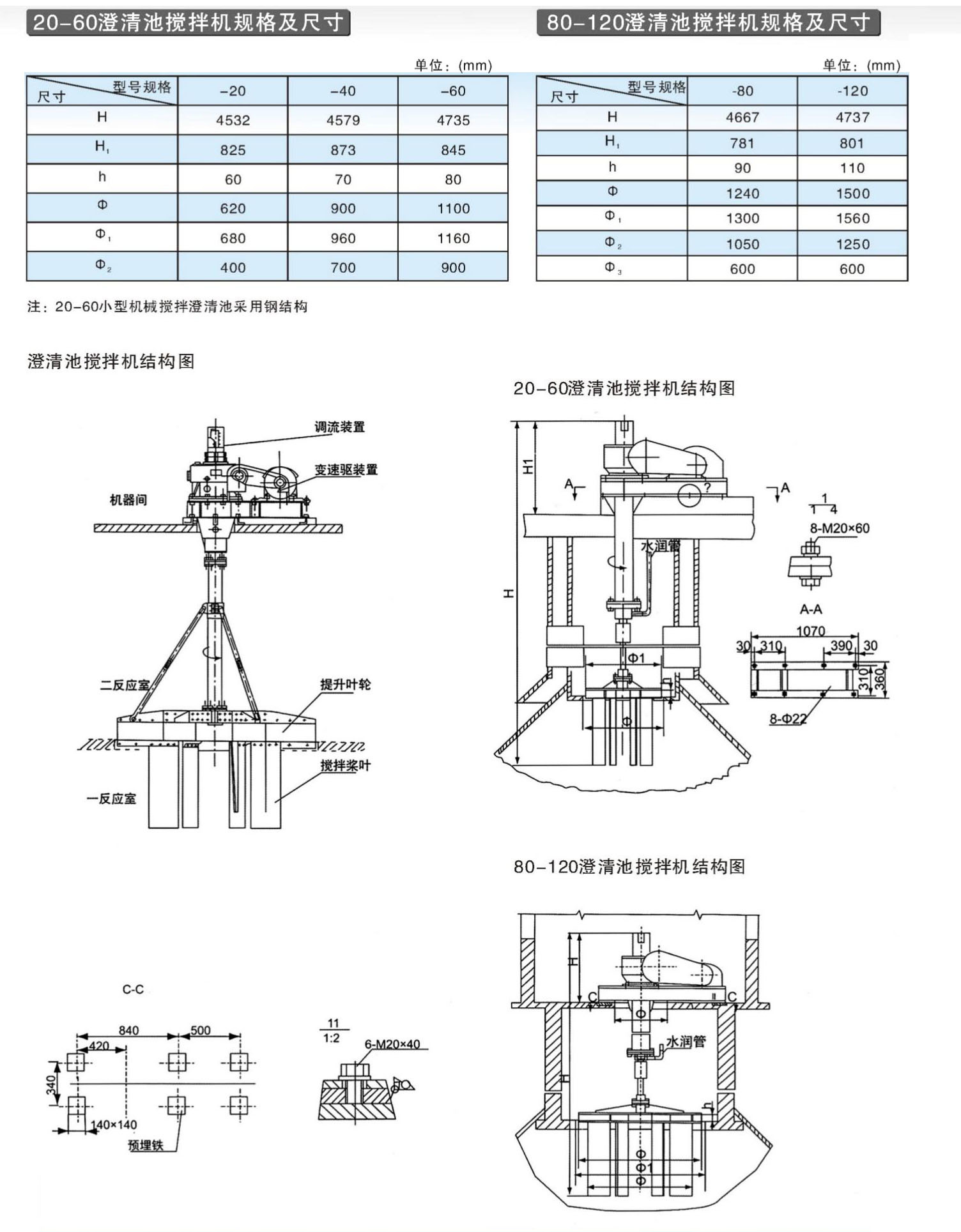

Structure and working principle

The mixing is mainly composed of flow control device, variable speed drive device, and mixer spindle. Lifting impeller and mixing paddle and other components.

The scraper is mainly driven by variable speed. The transmission shaft and scraping rake and other components are composed, when the diameter of the clarifier pool < 19.5m mixer shaft is a hollow shaft, the scraper shaft passes through it, it is a sleeve type center drive, the pool diameter is > 19.5m The two shafts are separated, and the scraper adopts gears

Pin chainring drive. The lower wheel paddle of the mixer impeller completes the mechanical reaction in the first reaction chamber of the clarification pool, so that the microfloc produced after dosing and mixing collides with the original iso flower in the reflux sludge again to form larger flocs, and then lifts from the impeller to the second reaction type, and then separates by bending to the clarification zone, the clear water rises out of the collection pipe, and the sludge flows back to the first reaction chamber in the lower part of the clarification area, and the scraper scrapes through the mud valve at the bottom of the pool to control and discharge. Achieve the effect of raw water clarification and separation.

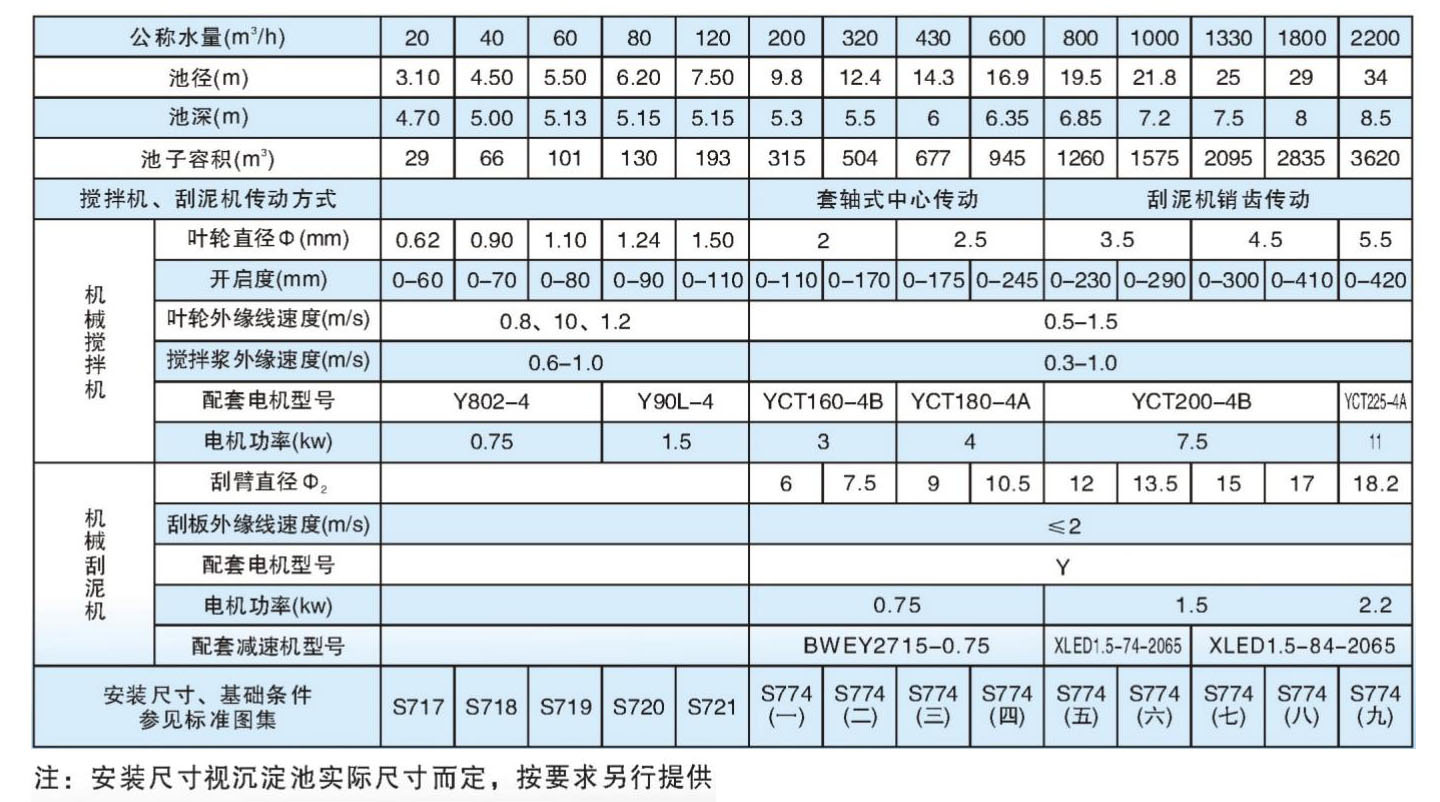

Technical data and installation size chart

Related products

Message